Metal Recycling

We at Vasoo Recycle are pioneer in metal scrap business. With our operations dating back to 1998, when we started a small firm dealing in both domestic and international trading of metal scrap. We setup a large infrastructure for trading with corporations and governments of different nations around the globe. It was in the year 2015 that we by adding metal processing and recycling operations to our business. That we transformed our trading business into a one stop metal recycling solutions. Dealing in ferrous metal which includes carbon steel, alloy steel, wrought iron, and cast iron etc. Non-ferrous metals which includes aluminum, copper, lead, zinc, and tin. Precious metals such as gold, platinum, silver, iridium, and palladium. Currently, our service portfolio for our clients consists of all the processes or steps involved in metal recycling process such as:

1. Trading ferrous and non ferrous metal scrap: We buy and sell all kinds of ferrous and non-ferrous metal scrap from any kind of raw materials to finished products both domestically and internationally.

2. Brokering Scrap metal deals: Through our wide clientele and connections around the globe we have developed through our experiences in business in last 20+ years. We also assist customers by brokering huge metal scrap deals around the world. By handling trade negotiations, documentations and costing analysis.

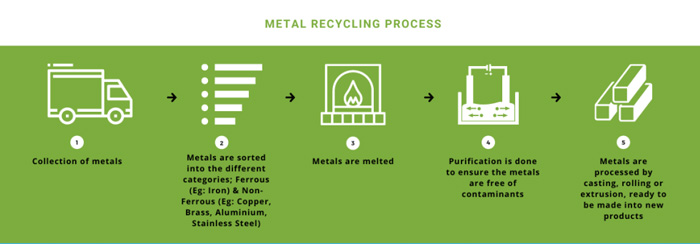

3. Recycling Metal Scrap: A comprehensive service of converting scrap metal to metal ingots without altering their properties in an environmentally sustainable manner. Our comprehensive metal scrap recycling process is described below.