Battery Recycling

Vasoo Recycle under the company name of Vasoo Metals is one of the largest scrap battery recycling company in India. With our 15 years of exclusive experience in lead acid battery trading, processing and professionally recycling of lead-acid batteries in an environmentally safe and socially responsible manner.

Vasoo Metals, which includes the recycling division known as Vasoo Recycle, is a significant player in the Indian scrap battery recycling industry. We have 15 years of expertise in the trading, processing, and professional recycling of lead-acid batteries in a way that is both safe for the environment and respectful of society.

At Vasoo, a battery recycling company, we are able to provide the highest rates for scrap batteries on both the local and international markets. We collect and recycle all battery kinds, including those used in solar panels, electric vehicles, inverters, and more. We recycle batteries in a way that prevents air and water contamination since we are a government-approved battery recycling in Delhi.

Is That So?

The lead industry is very interested in the recycling procedure for lead. These days, secondary lead smelters account for over half of the world's total lead output. Used lead-acid batteries (ISRI Rains) and lead scrap (ISRI Radio) are the significant inputs here since recycled batteries comprise more than 90% of the market.

When compared to other commonly recycled materials like paper and glass, lead has one of the highest rates in the world. It also has a higher recycling rate than any other metal, including copper, aluminum, or zinc.

The simple and energy-efficient recovery technology of lead recycling substantially contributes to sustainable development by lowering carbon emissions and relieving strain on nonrenewable resources.

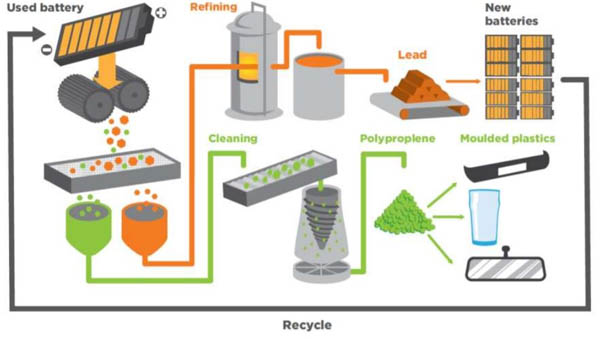

An outline of how we collect, sort, and recycle lead-acid batteries