Copper Cable Recycling

Since the company's founding in 2004, Vasoo Recycle, Copper Cable Recycling in Delhi, has been an industry leader in the recycling of copper cable. Now, with a plant in Neemrana, Rajasthan, under development, we are striving to attain the daily capacity of recycling copper wire that is ten times more than it is currently. Despite this, the recycling sector for copper wire is highly streamlined, with only a few leading firms managing the collection and sale of unwanted copper wires. Because of this, most of our business in the copper wire industry is conducted with importers, big contractors, and other companies that can guarantee a steady supply of waste copper wire shipments. However, as part of our mission to make our earth a more sustainable place, we are open to collecting items from various sources, including households, industries, local merchants, construction contractors, etc.

The importance of recycling copper wires

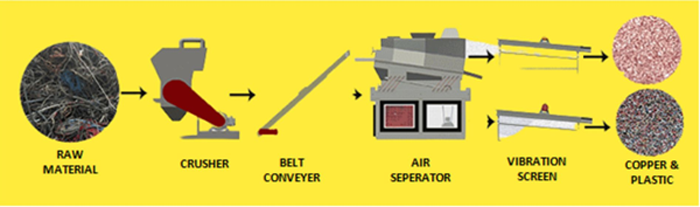

Copper wires typically comprise various components, some of which may be less recyclable, extractable, and ecologically beneficial than copper. However, pure copper may be recycled as a whole. Therefore, recycling copper wire is the most efficient way for businesses to profit from their waste of copper wire goods and equipment. Additionally, recycling copper wire is an excellent way for businesses to minimize the amount of trash generated at their job sites and have a beneficial influence on the community. Because your scrap copper is a valuable resource, working with us will allow you to put all your concerns out of your mind and free up your time to focus on more significant matters. Copper Cable Recycling Company in Delhi will be responsible for everything relating to the logistics, bifurcating, and recycling of copper wires. If you are interested in learning how to recycle copper wire on a construction site, refer to the procedures that are listed below:

If you want to learn how to recycle copper wire on a job site Refer Below mentioned steps: